Over the years many in the nuclear industry have looked at our pedigree for high quality project management and project execution and inspected our QMS.

Our fundamental capability to deliver high quality, fully documented, control, monitoring and vision systems have been key to our success in the nuclear sector.

#GAMP CATEGORIES EXAMPLES SOFTWARE#

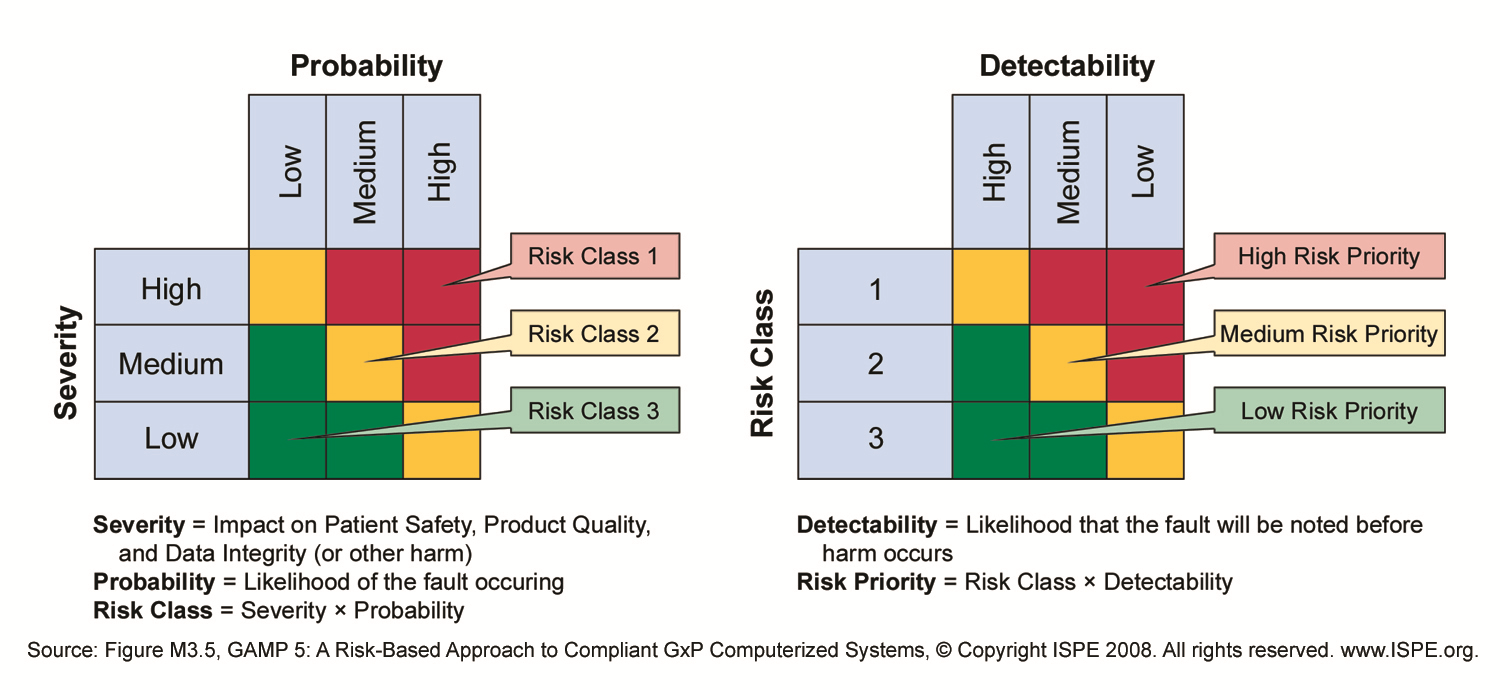

Projects ranging from installing additional safety functionality requirements on existing systems, creating replacement systems based on supportable hardware and software platforms or the reverse engineering and replacement of main control functions, all have been within the demands placed on ITS over the intervening years. Since 1998 ITS has performed projects in the nuclear decommissioning field. In today’s chemical world, like so many others, data is king and ITS Ltd has designed and built real time monitoring and reporting systems which link to ERP systems to automatically transfer plant production data to enable plant staff and management to make better decisions based on a single set of true values and analysis points. So from PLC through to DCS type applications on the hardware side and S88 /S95 compliant software systems where required, ITS Ltd has designed and built complete process plants, vessels pumps pipework and E&I systems and cabling from the ground up, from one company who takes its safety and CDM responsibilities seriously. Our systems are found in plants making useful products and materials including petrochemical and plastics, inorganics and fertilisers, paints and coatings and detergents and personal care products. The range of solutions ITS has provided over the last 30 years range from process control of large-scale continuous processes for basic and intermediate chemical products and materials, to batch processes of speciality chemicals. With a chemical engineering background and years of experience working for UK and global chemical manufacturers, ITS’ background is steeped in the chemical processing industry. ITS Ltd, together with other partners, known to the industry, means we can be on the road to a successful project together. ITS Ltd looks to add value from a solution delivery view, be it a control or management information system, or specialist data analysis requirement, we look to add value. Other issuing agencies with potential for the use of HIBCC and ICCBBA coding will be available in the future it is expected. In order to meet the latest EU MDR 2020 which will require that 2D Data Matrix and GS1-128 codes to be used going forward. Our more recent work in the industry has seen us involved in delivery of UDI solutions. This allowed ITS Ltd to become engaged in the medical device industry around 1997. Our knowledge of good practice requirements, of the 510k program and the changing requirements of the regulations authorities since 1997 when the FDA provided its De Novo classifications for Medical Devices and allowed the use of previous device data analysis to support subsequent device submissions. Be it a control or management information system, compliance or specialist data analysis requirement, we add value. Our own QMS is based around the GAMP®5 principles and we are both experienced and pragmatic in our delivery, you get what adds value and not documentation for the sake of documentation.Īs the biotech / biopharma industry has grown, so too has our knowledge and involvement in that from a regulatory point of view, but also, from a ‘value adding’ solutions delivery too. We started in the GxP era, pre GAMP® and have been involved in the developments of GAMP® from v1 to v5, including additions like 21CFR11 compliance and Serialisation, Data Integrity and have had an active involvement in several ISPE SIG groups over the years too.

Since 1991 we’ve grown as a business providing systems and support to the pharms industry. ITS Ltd experience in the pharmaceutical sector started nearly 30 years ago.

0 kommentar(er)

0 kommentar(er)